For established beauty brands, ensuring consistent quality and meeting large-scale production demands is crucial. At Queen Brush, we specialize in providing scalable manufacturing solutions tailored to the unique needs of global brands, offering unparalleled expertise, precision, and efficiency.

Meeting the Demands of High-Volume Orders

At Queen Brush, we pride ourselves on our ability to meet the needs of brands requiring large-scale orders. Our advanced production facilities and experienced team ensure top-notch quality, efficient workflows, and on-time delivery for every project.

Efficient Workflow

Our streamlined production system is designed to minimize delays and maximize efficiency, starting from the moment you share your requirements. We quickly understand your needs, which helps reduce communication time and eliminates unnecessary back-and-forth. This efficiency allows us to focus on production and deliver high-quality brushes within tight deadlines. Whether it’s preparing for a product launch, managing seasonal demands, or replenishing high-demand items, our process ensures your order is handled with precision and speed.

Customized Solutions

We specialize in tailoring our products to your brand’s exact specifications. Whether it’s creating unique shapes, applying custom logos, or designing bespoke packaging, we work closely with you to bring your vision to life. However, in the makeup brush industry, custom solutions require certain minimum order quantities (MOQs) to be feasible.

Many clients just starting their brands often request small custom orders, such as 50 or 100 brushes, but these quantities are not viable for customization. Our standard MOQs start at 1,000 units per style. For more complex designs or intricate requirements, the MOQ may increase to 2,000 units or more. Larger order quantities also benefit from economies of scale, allowing us to offer a lower unit price, making it more cost-effective for established buyers with mature markets.

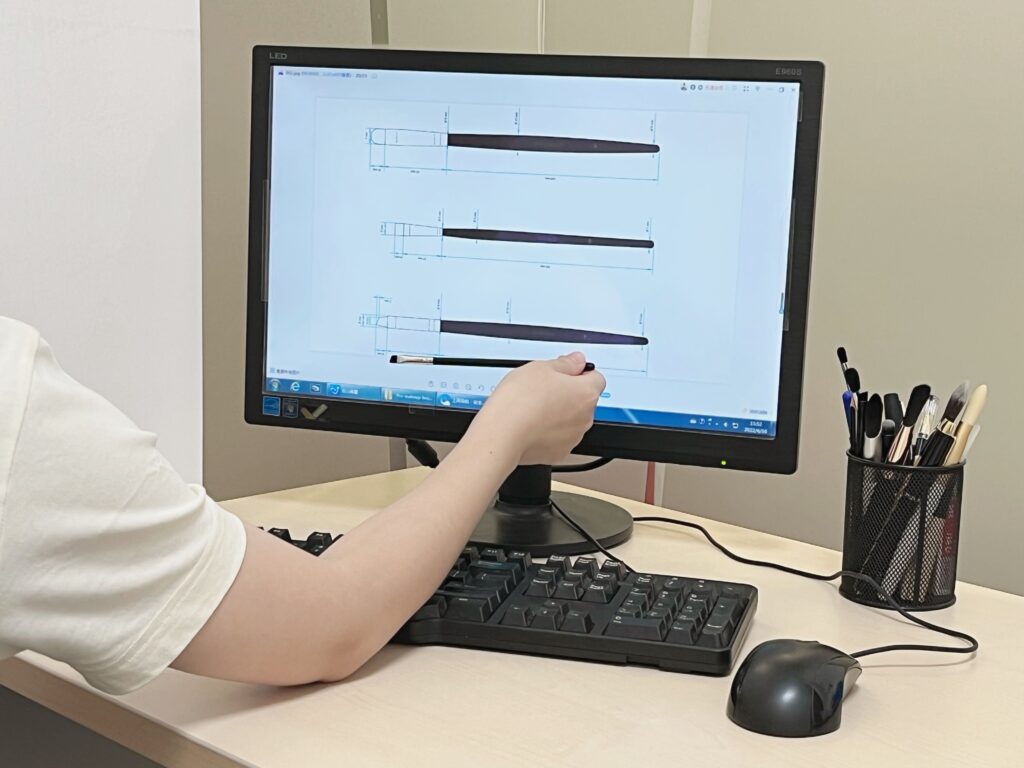

The 20-Step Production Process: Precision and Expertise

At Queen Brush, our meticulous 20-step production process is a blend of cutting-edge technology and artisanal craftsmanship, ensuring every makeup brush meets the highest standards of quality. Below is a detailed breakdown of 10 key steps in this process, showcasing the precision and expertise behind each brush we create.

1. Material Selection

The process begins with sourcing premium materials for each brush component. From high-quality synthetic or natural bristles to durable ferrules and carefully selected wooden or plastic handles, each material is chosen for its performance, aesthetics, and longevity.

2. Bristle Preparation

The bristles are dyed, cleaned, and treated to ensure they are hygienic, soft, and durable. This step is essential for achieving the perfect balance between flexibility and firmness required for makeup application.

3. Bristle Shaping and Trimming

Using advanced equipment and skilled craftsmanship, bristles are shaped and trimmed to meet specific density and length requirements. This precision ensures optimal performance for tasks like blending, contouring, or powder application.

4. Ferrule Cutting and Polishing

Ferrules are cut from durable materials such as aluminum or copper, then polished to achieve a smooth, seamless finish. This ensures both functionality and an aesthetically pleasing look that complements the overall brush design.

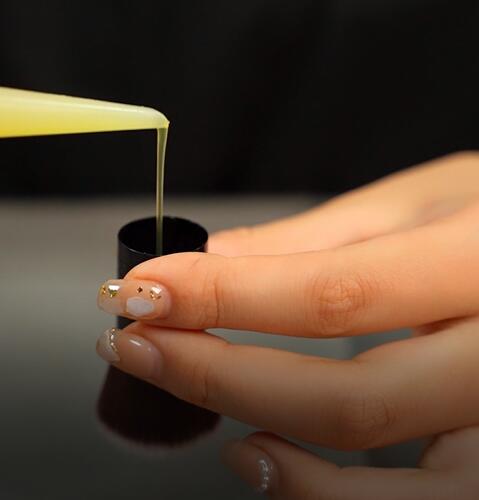

5. Ferrule Assembly

Skilled workers assemble the ferrules with the bristles, ensuring a secure and tight fit. The ferrule’s role is to hold the bristles in place while maintaining a strong bond with the handle.

6. Handle Crafting

Handles are carved or molded according to the design specifications. For wooden handles, they are sanded and polished to remove imperfections, while plastic handles are checked for uniformity in shape.

7. Painting and Coating

Handles are painted or coated with precision, following your chosen color scheme and finish. Multiple layers of paint or lacquer are applied to achieve a smooth, durable surface resistant to chipping or fading.

8. Logo Application

Your logo is applied to the handle using advanced techniques such as silk screen printing, heat stamping, or laser engraving. This step ensures the logo is clear, durable, and aligned with your brand’s aesthetic.

9. Assembly and Adhesion

The handles, ferrules, and bristles are assembled into a single unit using high-quality adhesive. Each brush is then set aside to allow the adhesive to cure properly, ensuring a strong and durable bond.

10. Quality Control and Testing

Every brush undergoes rigorous quality control checks at this stage. We test for durability, performance, and consistency to ensure each piece meets our strict standards before packaging. Brushes are also tested for softness and usability to guarantee customer satisfaction.

This 10-step process is a snapshot of the precision and care we apply to every makeup brush. The additional steps include fine-tuning details, packaging, and final inspections, all of which contribute to the exceptional quality of Queen Brush products.

Comprehensive Quality Assurance

At Queen Brush, we know that exceptional products begin with an unwavering commitment to quality. Our comprehensive quality control system is designed to ensure that every brush meets your brand’s high standards and exceeds your customers’ expectations. With a meticulous approach that includes over five thorough inspections throughout the production process, we guarantee the reliability and performance of each item.

Raw Material Inspection: Full-Scale Quality Checks

Before production begins, we perform a 100% inspection of all raw materials, including bristles, ferrules, and handles. This ensures that every component meets our strict quality standards. From synthetic fibers to natural bristles, and from aluminum ferrules to wooden handles, only the best materials are approved for production.

In-Process Checks: Precision at Every Stage

During production, we conduct rigorous inspections at every major phase to identify and resolve potential issues early. Key checkpoints include:

- Bristle Bundling: Ensuring consistent density, length, and shape of the bristles.

- Ferrule Assembly: Verifying a secure and seamless attachment to the handle.

- Handle Crafting: Checking for uniform finishes, paint consistency, and flawless design details.

Our team of skilled workers and quality controllers works hand-in-hand to maintain precision at every step, ensuring minimal defects.

Final Product Testing: Delivering Perfection

Once production is complete, each brush undergoes a comprehensive final inspection, where we evaluate:

- Consistency: Confirming uniform bristle density and handle design.

- Durability: Testing the strength of attachments and overall construction.

- Performance: Ensuring that each brush functions as intended, providing the smooth application your customers expect.

This multi-layered process guarantees that the finished products align with your brand’s promise of excellence.

Commitment to Excellence

By incorporating five or more quality checks across the production cycle, we ensure that every brush leaving our factory is flawless. Whether your order consists of thousands of units or an exclusive collection, you can trust that Queen Brush products meet the highest quality standards, every single time.

A Trusted Partner for Your Brand’s Success

At Queen Brush, we specialize in meeting the exacting standards of professional buyers. Whether you need to scale production for established collections or develop custom designs for new launches, we deliver reliable, high-quality manufacturing solutions tailored to your brand’s goals.