Just as the Queen is the monarch of everything she surveys, we strive to provide the best quality cosmetic brushes in the world. For that, we do not compromise on the quality aspect because we understand that quality is the only thing capable of withstanding the test of time. So, our cosmetic accessory products go through the most stringent quality tests before they are packed off to their respective destinations. We know that providing the highest quality standards is critical to attracting new customers and retaining the existing ones.

We follow structured quality control procedures that work at every production stage, from the raw material procurement process to the dispatch of the final products to our customers.

Makeup brush bristles

Queen Brush manufactures animal hair and synthetic fiber cosmetic brushes. We source our requirement of animal hair from suppliers maintaining healthy livestock. Besides goat and sheep hair, we procure horse and mink hair based on our customers’ requirements. We concentrate on aspects like softness and color and separate them accordingly.

Hair shading is another critical factor we focus on when conducting quality control tests on animal hair. Hair shading refers to the techniques by which hair is processed and dyed. Accordingly, we separate the shaded hair from the non-shaded samples to prevent them from mixing when manufacturing the makeup brushes.

Animal hair form knots for makeup brushes as per the type, size, and density of makeup brush bristles. We select the appropriate length, cut the knots, and verify each hair’s thickness with the sample. Hair that has been shed naturally has a different density than cut hair. In addition, animal fur can have split ends. Our quality control process removes such defective hair from the production line to ensure that the best and evenly cut hair is used for manufacturing our makeup brushes.

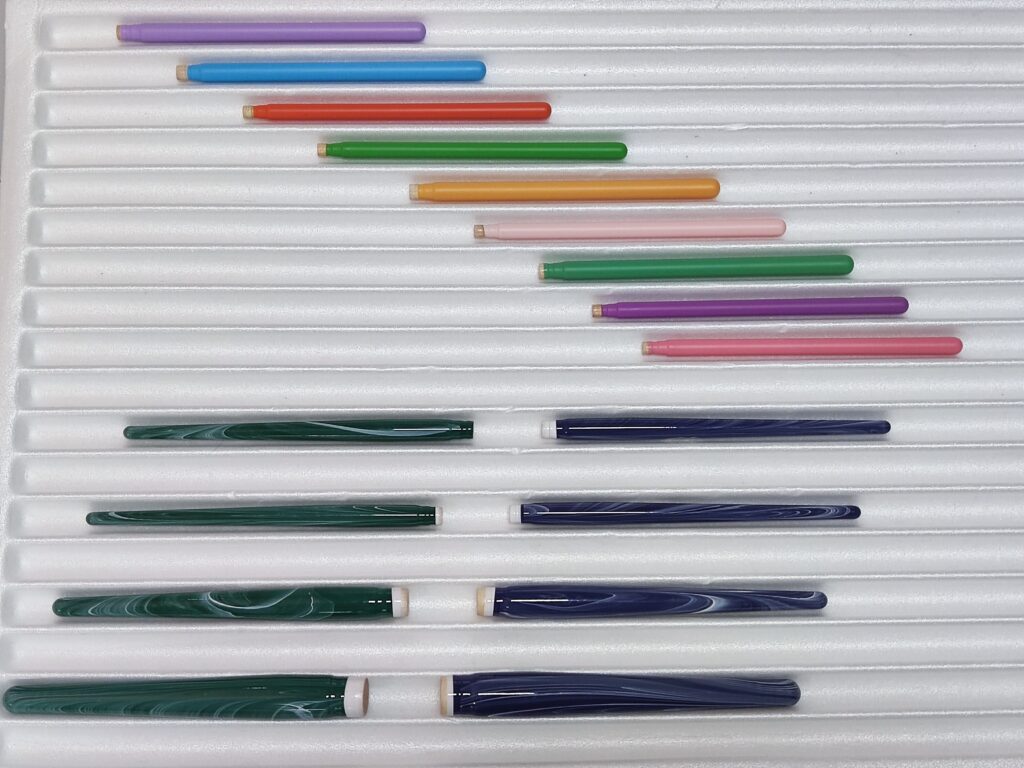

- Synthetic Fibers

Not every brush brand requires animal hair. Today, the trend is more toward synthetic fibers. We have a dedicated pool of trusted raw material suppliers who understand our quality control stipulations and provide us with high-quality raw materials that are safe, eco-friendly, and match up to the high standards we have developed over the years.

Besides, we have dedicated production facilities for processing the raw materials according to our client’s preferences. Furthermore, our raw materials pass through a strenuous quality control inspection process to ensure that we manufacture the best quality cosmetic brushes. This process identifies and filters impure and defective materials to maintain our stipulated standards.

- Stage-wise inspection

We inspect the raw materials at every stage of production. Weighing the hair or synthetic fibers is crucial before commencing the manufacturing process. We weigh each sample carefully using precision weight equipment to ensure that the hair weight in our different makeup brushes is consistent with the sample.

- Hair Coloring

Coloring the hair or synthetic fibers is crucial. We use natural, organic colors and ensure they do not contain toxic substances. The coloring process is meticulously monitored to ensure a uniform finish according to our customer’s preferences.

Ferrule Selection

The ferrule is a critical ingredient of cosmetic brushes because it protects the brush from splitting or corrosion. We at Queen Brush choose our ferrules carefully to match the brush bristle size and the brush category. We offer an exciting range of ferrules made from aluminum, copper, nickel, or plastic for our customers to choose from.

Our quality control standards stipulate selecting the ideal ferrule of the perfect size and appropriate color. The standards also ensure the ferrules do not have any scratches. We discard imperfect ferrules and remove them from the production line after careful inspection. The ferrules are crucial because they provide our brushes with the protection they need.

Every ferrule piece passes through a salt spray test to determine the oxidation levels. Materials with high oxidation levels tend to rust quickly. The salt spray test machine subjects each ferrule with calibrated amounts of salt for 24 hours. The ferrules that clear the salt spray test then proceed to the production line. The unfit ferrules are discarded.

Handle Selection

Generally, customers prefer wooden handles. However, we can also supply plastic handles if the situation demands it. We carefully choose the brush handles to match the color, size, and category. First, our quality standards do not have any scope for scratches on the handle. Secondly, we test the humidity of the wood used as handles for our brushes and ensure the level is maintained at 16%.

We use high-grade plastic for our brushes if the customer requires the same. But, again, we concentrate on the color and size and ensure there are no scratches on the surface.

The brush handles are subject to an ultraviolet weathering test to check for discoloration when subjected to UV rays. This test ensures that our brush handles do not turn yellow on exposure to sunlight. Thus, it enhances the product’s durability and lengthens its lifespan considerably.

Final Product – Stringent Quality Control

- Humidity and Constant Temperature Test

The final products are placed in the temperature and humidity test machine that checks each product for material changes on the handle and the glue materials at high and low temperatures.

- Firmness test

We follow a unique Tensile test to ensure the firmness of the handles, bristles, and ferrules. This test helps segregate the defective brushes from the lineup. Besides, it provides information on the exact amount of glue to produce a durable product.

- Logo Adhesion Test

Our makeup brushes are available with our logo. Alternatively, we offer customers the option to print their respective logos. We use different methods of engraving the logo, such as Silk Screen, Hot Silver, Bronzing, Laser Printing, or Engraving.

The Logo Adhesion test is critical to ensure that the printed logo remains intact. We stick adhesive tape over the logo and remove them after some time. It helps test the quality of the adhesion of the logo to the brush handle.

- Clean the brushes thoroughly.

Before packing the brushes, the final quality control test ensures no fingerprints, dust specks, or glue residue on the brushes and handles. This process involves cleaning each brush thoroughly.

- Post Packaging Tests

Once packed, we recheck the packages to ensure they are of the right size and have the correct printing. We also ensure there are no fingerprints on the box. The packets are also tested for vibrations they could endure during transportation. This simulated test confirms that the brushes and the boxes are firm, durable, and fit for transport.

Wrap Up

Queen Brush emphasizes maintaining the highest quality standards are each production stage, from the raw materials to the final dispatch. We endeavor to offer products, all types of makeup brushes in bulk with brand logo, of the highest quality to our buyers.